- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

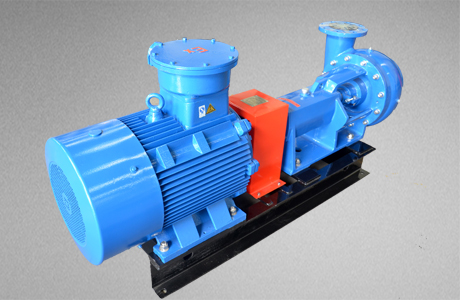

- Centrifugal Pump

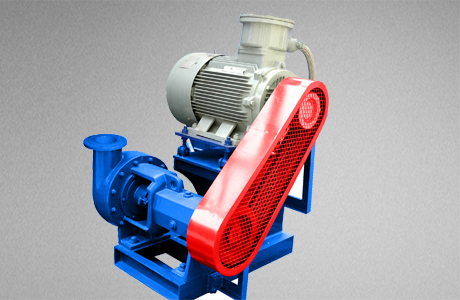

- Shear Pump

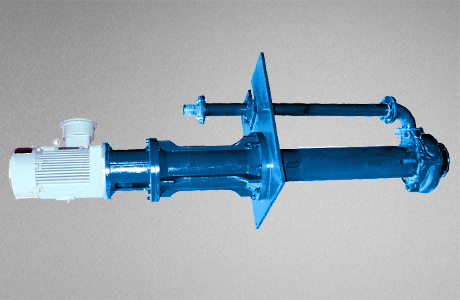

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

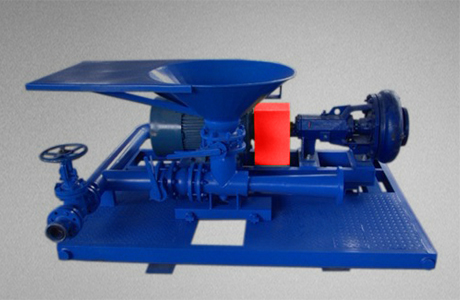

- Jet Mud Mixer

- Desilter

- Water Tank

- Mud Tank

- LS1850 Shale Shaker

- Diesel Tank

- KQG30 Automatic Tank Cleaning

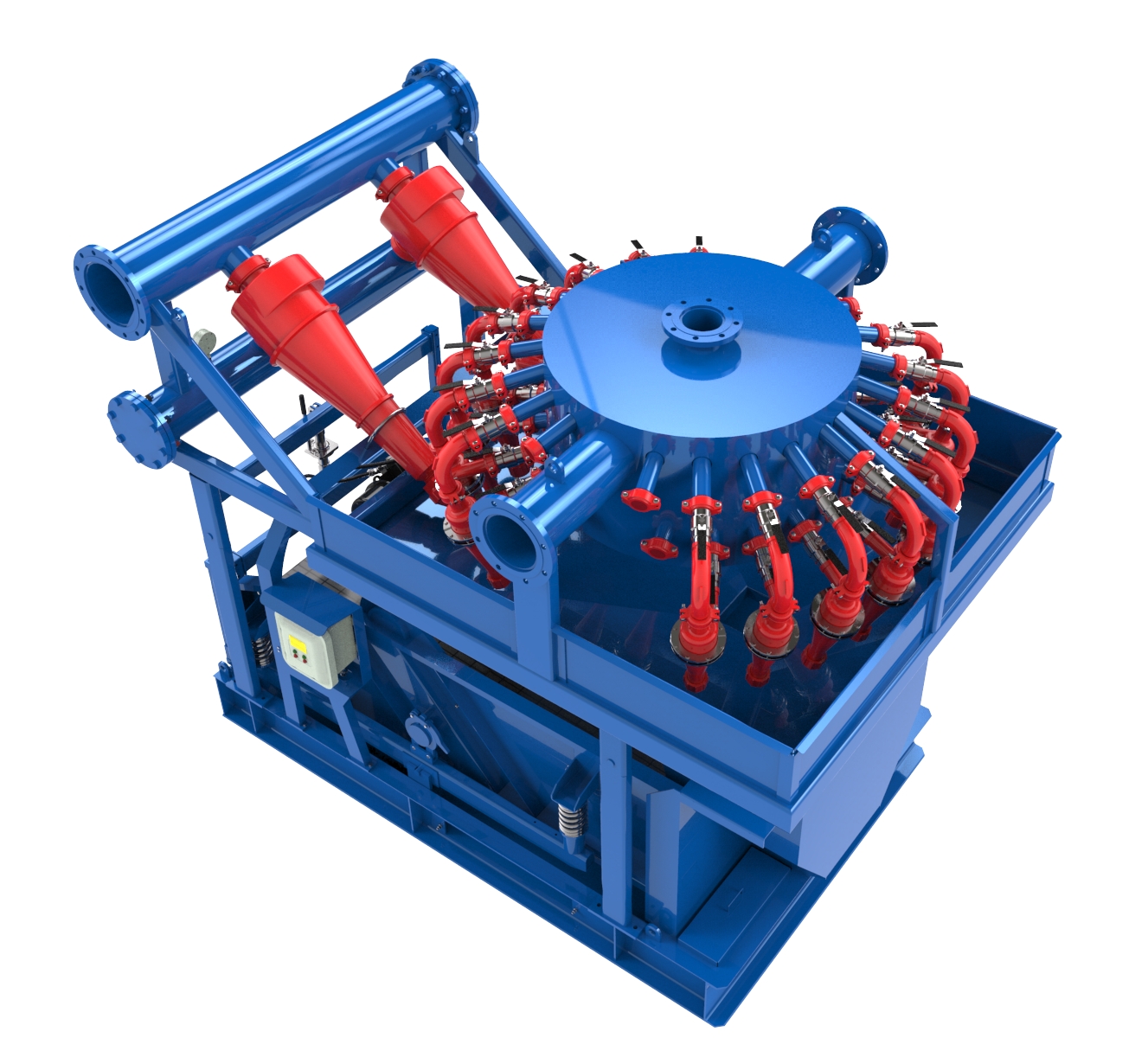

- MD210 Drilling Mud Cleaner

- Balanced Elliptical Motion Shale Shaker

- Oilfield Drilling Mud Desander

-

Solids Control System

- Drilling Mud Cooling System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

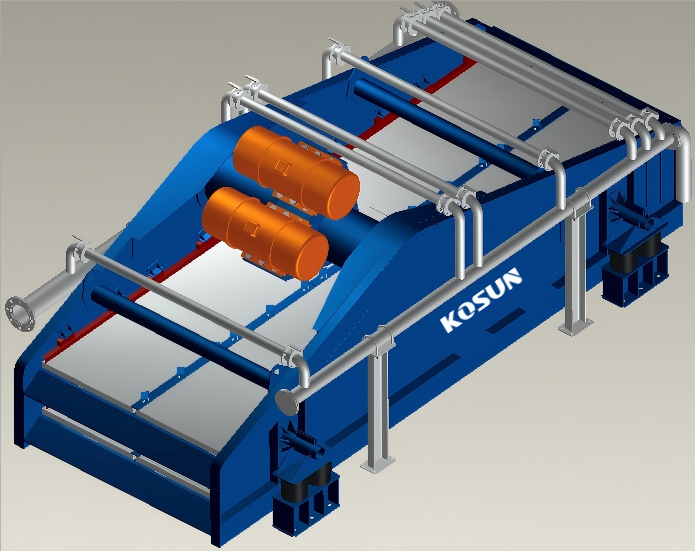

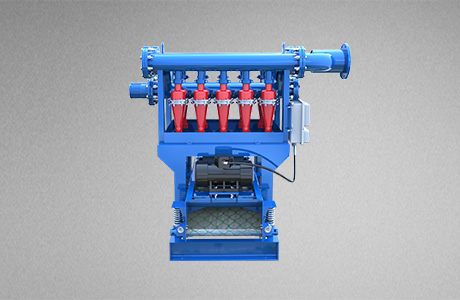

LS1850 Shale Shaker

LS1850 Shale Shaker adopts three-phase asynchronous vibration motor as the vibration source, and is dragged by two motors to reverse self-synchronous rotation, which is the periodic reciprocating motion of the screen body along a straight line, so as to achieve the purpose of solid-liquid separation. It is mainly used for solid-liquid separation equipment in the process of mining, traversing shield and environmental protection treatment. The shale shaker can be used alone, or can be used in double or multi-combination.

Xi 'an Kosun LS1850 Shale Shaker adopts three-phase asynchronous vibration motor as the vibration source, and is dragged by two motors for reverse self-synchronous rotation, which is the sieve body to do periodic reciprocating motion along a straight line, so as to achieve the purpose of solid-liquid separation. The double-layer screening design can effectively subdivide the material, and the total screen area reaches 18 square meters (9 square meters per layer), ensuring that the material has sufficient residence time on the screen, so as to achieve efficient screening effect.

Application:

LS1850 Shale Shaker is mainly used in mining, through the shield, environmental protection treatment process of solid-liquid separation equipment,

the vibrating screen can be used alone, can also be used in double or multiple.

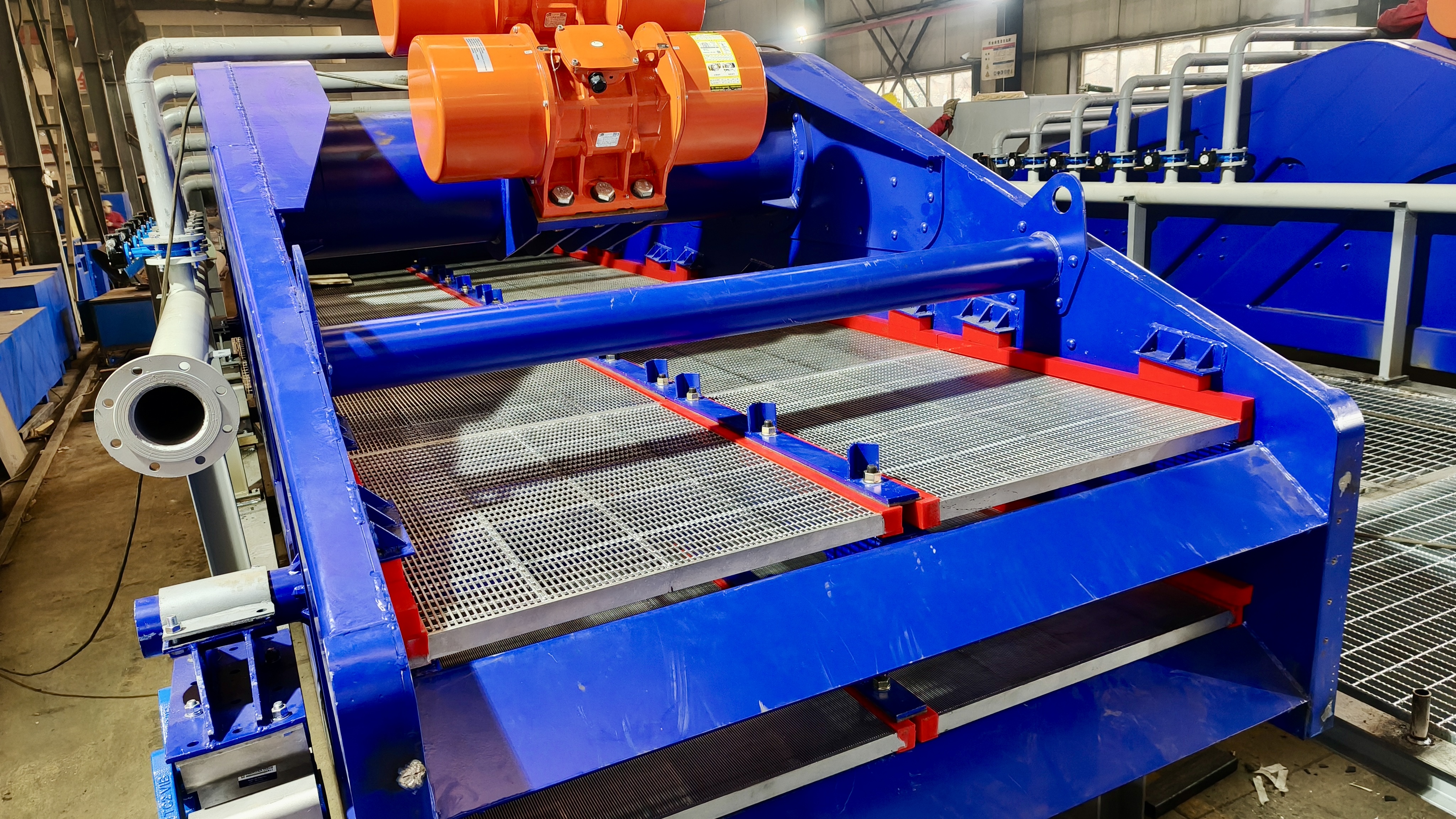

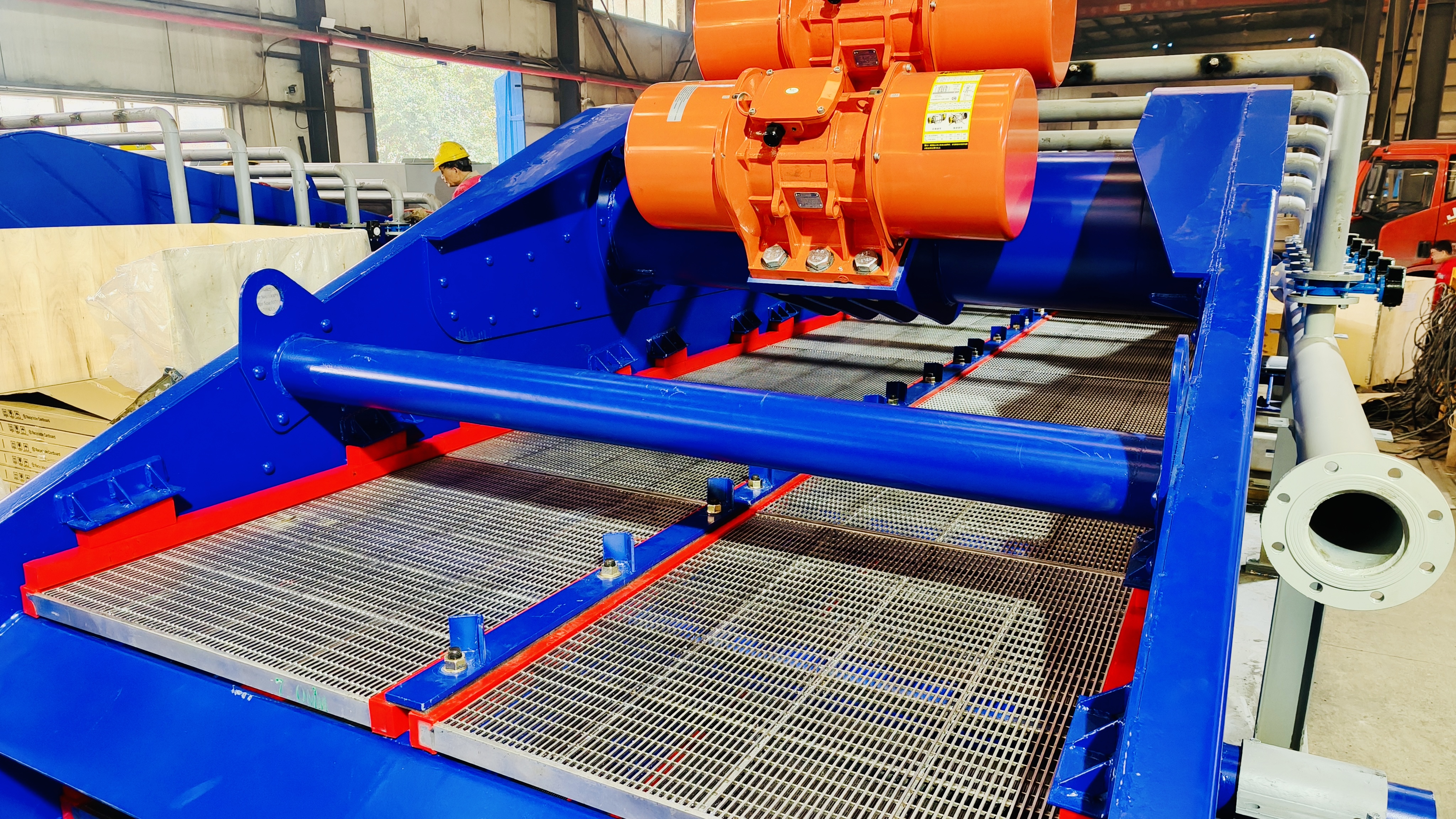

LS1850 Shale Shaker Features:

1, choose OLI (international well-known brand) two 7kw vibration motor with large excitation strength, to ensure strong vibration performance and stable operation.

2, the selection of high strength, good plasticity, corrosion resistance and beautiful and durable stainless steel seam screen, through the wedge and the combination of the lock bolt fixed,

to ensure that the high frequency vibration is stable and not fall off, and easy to replace.

3, the use of international well-known brand Tenida imported spring, to provide excellent flexibility and reliability.

4. The system supports manual and automatic operation modes. In the automatic mode, the PLC program communicates with the host computer to achieve the purpose of automatic control,

with a high degree of automation, simplifying the operation process and improving work efficiency.

send an E-mail us

send an E-mail us- We're here to help:

- Easy ways to get the answers you need.

+86 13379250593

+86 13379250593 office@adkosun.com

office@adkosun.com

Services

Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial sale;Your profits with quality parts and expert service.

Linear Motion Shale Shaker

Linear Motion Shale Shaker Decanter Centrifuge

Decanter Centrifuge Mud Cleaner

Mud Cleaner Vacuum Degasser

Vacuum Degasser Centrifugal Pump

Centrifugal Pump Shear Pump

Shear Pump Submersible Slurry Pump

Submersible Slurry Pump Mud Agitator

Mud Agitator Mud Gun

Mud Gun Jet Mud Mixer

Jet Mud Mixer Desilter

Desilter