- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- Mud Tank

- Diesel Tank

- MD210 Drilling Mud Cleaner

- Balanced Elliptical Motion Shale Shaker

- Oilfield Drilling Mud Desander

-

Solids Control System

- Drilling Mud Cooling System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

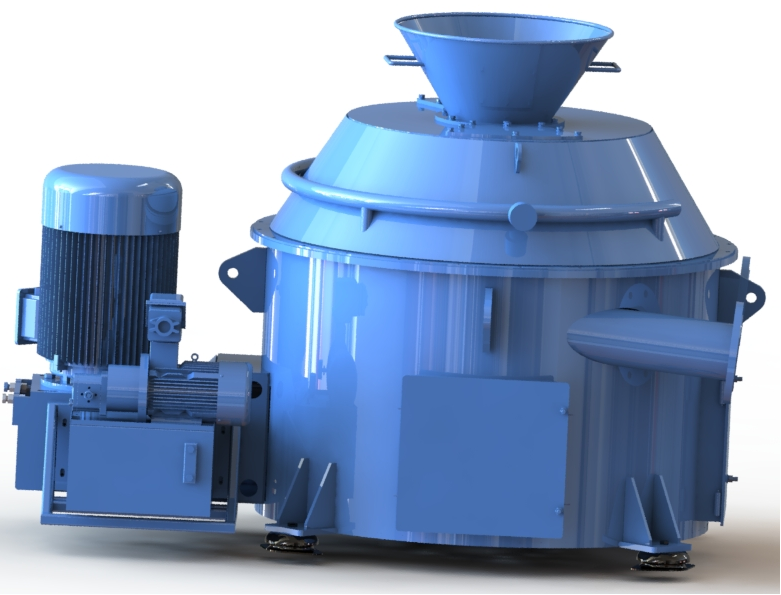

Vertical Cuttings Dryer

Vertical Cuttings Dryer( Vertical Centrifuge) produced by KOSUN is a type of vertical centrifuge, which can perform solid/liquid separation through centrifugal separation. The vertical cuttings dryer can effectively recover the liquid phase in drilling cuttings, making the solid phase become very dry. It is suitable for water-base mud, oil-base mud and synthetic base mud.

send an E-mail us

send an E-mail us- We're here to help:

- Easy ways to get the answers you need.

+86 13379250593

+86 13379250593 office@adkosun.com

office@adkosun.com

Features

Vertical Cuttings Dryer( Vertical Centrifuge) produced by KOSUN is a type of vertical centrifuge, which can perform solid/liquid separation through centrifugal separation. The vertical cuttings dryer can effectively recover the liquid phase in drilling cuttings, making the solid phase become very dry. It is suitable for water-base mud, oil-base mud and synthetic base mud. By recovering the mud in drilling cuttings, the vertical cuttings dryer can reduce the drilling cost and cut down environmental pollution. With handling capacity of 40-60 T/h, the oil on cuttings (OOC) of drilling cuttings can be reduced to lower than 5% (w/w) after treatment, meeting the international emissions standards and environmental protection requirements. The vertical centrifuge can also be applicable for drilling waste management in onshore and offshore drilling.

APPLICATIONS

Offshore and onshore projects where the recovery of valuable drilling fluid from cuttings, as well as recovery of whole mud lost from shaker failure, rig motion and screen blinding are priorities.

PROBLEMS

More stringent cuttings-discharge regulations have pressured operators and drilling contractors to reduce drilling waste volumes and recover premium products for reuse.

SOLUTIONS

The vertical cuttings dryer features a state-of-the-art design that can process varying amounts of cuttings and fluids, typically up to 60 tons per hour. Dry solids discharged from the dryer are typically≤5% oil content by wet weight.

ECONOMICS

The vertical cuttings dryer improves overall cost-efficiency, producing reduced amounts of extremely dry cuttings for disposal and recovering valuable fluid for reuse. It is effective with water-, oil- and synthetic-base drilling fluids.

Features and Benefits:

Environmental and cost

• Highly effective liquids/solids separation minimizes fluid content of cuttings

• Reduces waste-disposal volumes

• Effective separation reclaims high percentages of fluid that can be reused in the active mud system

• Recovers whole mud lost from shale shaker failure, rig motion and screen blinding, that is cost- effective.

• Reduces waste-disposal volumes

• Effective separation reclaims high percentages of fluid that can be reused in the active mud system

• Recovers whole mud lost from shale shaker failure, rig motion and screen blinding, that is cost- effective.

Operational Advantages

• Programmable Logic Controller (PLC), with automatic warning indicators, monitors temperature, torque, oil flow and operating hours

• High-capacity, continuous feed units have the throughput to keep up with drilling

• Tungsten-carbide-coated, independently adjustable flights reduce wear and ensure optimal tolerance

• Handrail and walkways is convenient for operators to do routine maintenance work, that can reduce risk to personnel

• Different kinds of screens can meet various operation requirements

• High-capacity, continuous feed units have the throughput to keep up with drilling

• Tungsten-carbide-coated, independently adjustable flights reduce wear and ensure optimal tolerance

• Handrail and walkways is convenient for operators to do routine maintenance work, that can reduce risk to personnel

• Different kinds of screens can meet various operation requirements

Ease of Maintenance

• Normal wear parts are easily accessible from the top of the unit; belts are easily

• changed without removing gear assembly

• Interchangeable tungsten carbide flights protect rotor and gear box from excessive erosion, minimizing main component failure

• Explosion-proof motors and control panels can be certified with CE/ATEX

Tags:VERTI-G cuttings dryer,Cuttings dryer,Vertical Cuttings Dryer,vertical centrifuge price,vertical centrifuge manufacturer,vertical Centrifuge, drill cuttings dryer, Solid Control Cutting Dryer, Mud Cutting Dryer , Drilling Waste Cutting dryer, Vertical Cuttings dryer for drilling.

• changed without removing gear assembly

• Interchangeable tungsten carbide flights protect rotor and gear box from excessive erosion, minimizing main component failure

• Explosion-proof motors and control panels can be certified with CE/ATEX

Tags:VERTI-G cuttings dryer,Cuttings dryer,Vertical Cuttings Dryer,vertical centrifuge price,vertical centrifuge manufacturer,vertical Centrifuge, drill cuttings dryer, Solid Control Cutting Dryer, Mud Cutting Dryer , Drilling Waste Cutting dryer, Vertical Cuttings dryer for drilling.

Services

Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial sale;Your profits with quality parts and expert service.

Vertical Cuttings Dryer

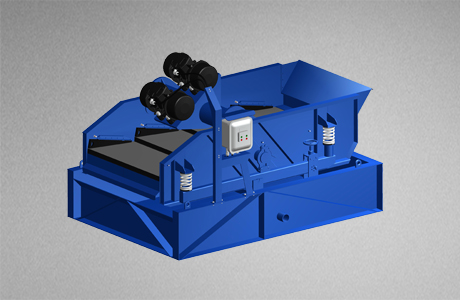

Vertical Cuttings Dryer Hi-G Dryer,Drying Shaker

Hi-G Dryer,Drying Shaker Screw Pump

Screw Pump VC700 Vertical Cuttings Dryer

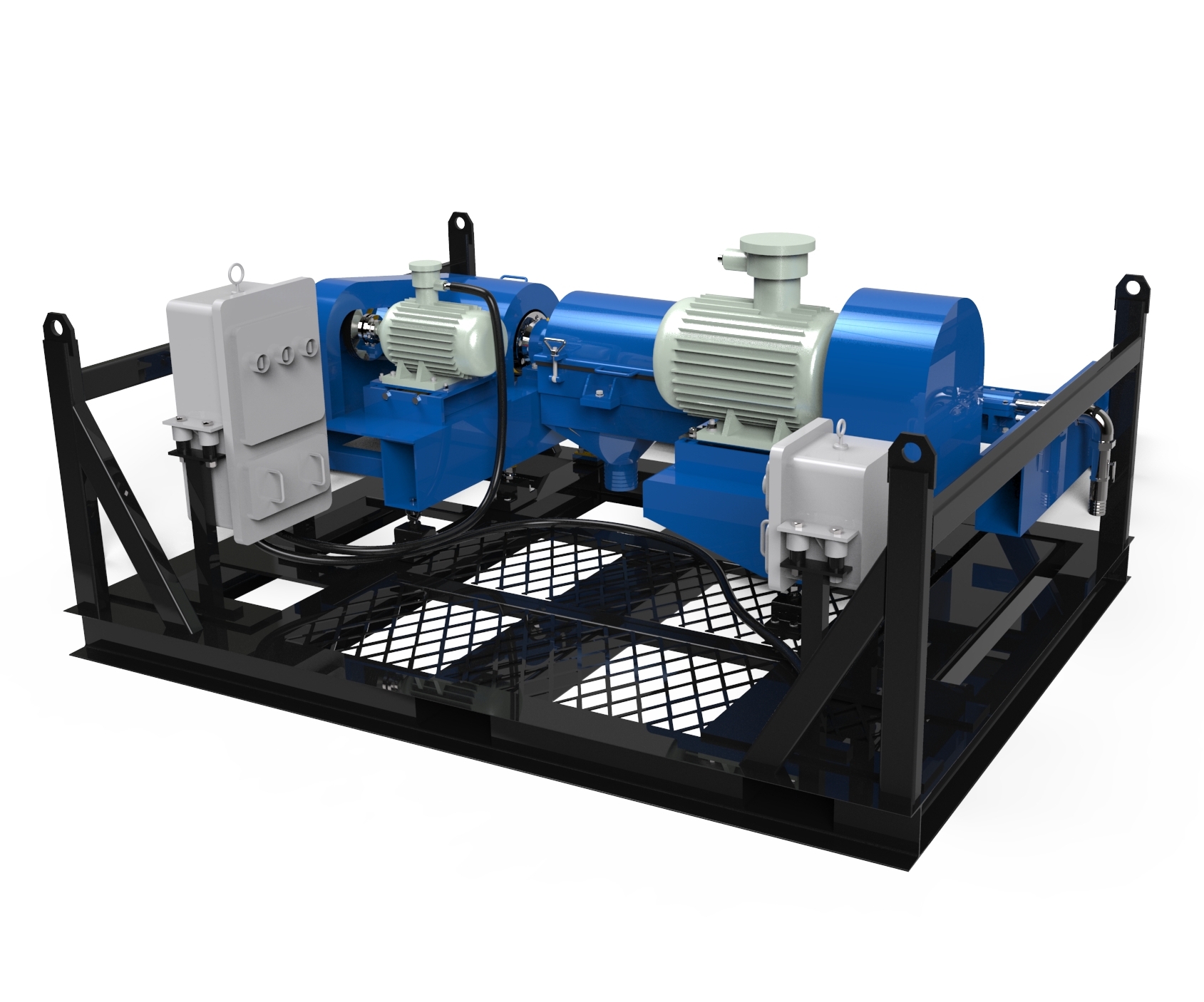

VC700 Vertical Cuttings Dryer D Series Decanter Centrifuge

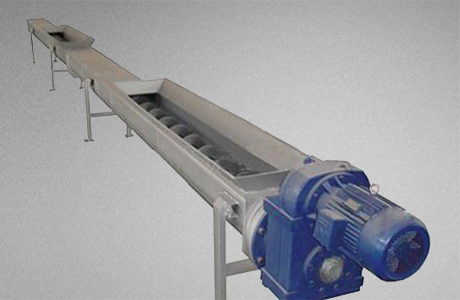

D Series Decanter Centrifuge Screw Conveyor

Screw Conveyor