- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- Mud Tank

- LS1850 Shale Shaker

- Diesel Tank

- MD210 Drilling Mud Cleaner

- Balanced Elliptical Motion Shale Shaker

- Oilfield Drilling Mud Desander

-

Solids Control System

- Drilling Mud Cooling System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

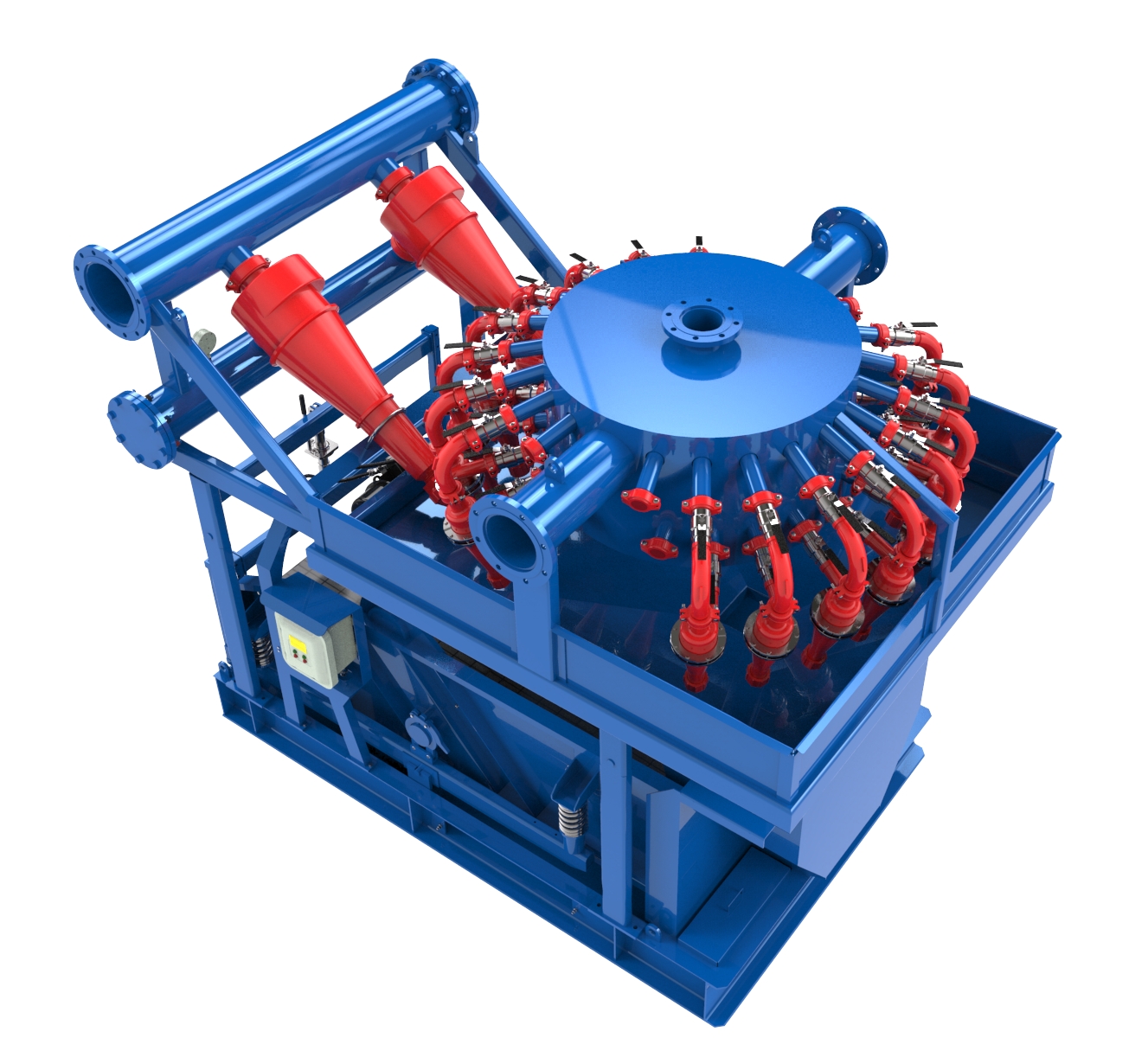

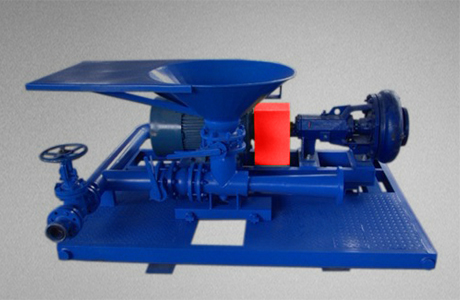

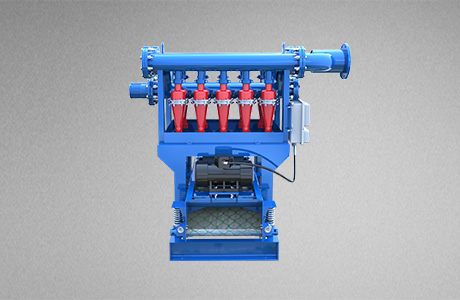

MD210 Drilling Mud Cleaner

KOSUN MD210 drilling mud cleaner is a second and third stage solid control equipment in the drilling mud solid control system. It further separates impurities such as fine sand from the mud that has been processed by the shale shaker, allowing the mud to enter the fourth-level separation equipment.

send an E-mail us

send an E-mail us- We're here to help:

- Easy ways to get the answers you need.

+86 13379250593

+86 13379250593 office@adkosun.com

office@adkosun.com

Features

The main components of the MD210 drilling mud cleaner include the screen frame, vibrating motor, screen cloth tensioning system, angle adjustment system, locking device, electrical system, desilter, desander, etc. The MD210 drilling mud cleaner can be used alone or the underflow vibrating screen can be used as a parallel backup device for the first-level solid control shale shaker. Our company can provide the corresponding diversion manifold.The underflow shaker screen LS703 of the MD210 drilling mud cleaner is a high-frequency linear vibrating machine. It is equipped with three screen frames and two vibrating motors, and has the feature of manually adjusting the screen frame angle (AWD) during drilling. When the LS703 shaker screen is in operation, the screen frame angle can be adjusted between -1° and +5°. Thanks to the innovative structural design, the LS703 shaker screen can efficiently separate drill cuttings. The vibrating motors are fixed to the screen frame and positioned on the screen bed with high-strength support beams. This positioning method allows the excitation force (G-force) to directly act on the screen cloth. The vibration-isolation device protects the base frame from the influence of screen frame vibration. The screen bed is slightly raised to facilitate the tensioning of the screen cloth. Tensioning the screen cloth in this way can improve its performance and extend its service life. The mud is fed into the LS703 shaker screen through the desilter, desander collection pan, or feed box.

The desilter and desander cyclones are designed based on the principle of particle settling. The drilling fluid, as the separation medium, enters the cyclone along the inner wall in a helical path under a certain pressure and velocity generated by the sand pump. Coarser particles spiral down along the inner wall of the cyclone and are discharged from the underflow outlet, separating on the finer mesh vibrating screen below. The remaining medium spirals upward along the cyclone and enters the next level separation equipment for further purification through the overflow outlet.

To provide the required flow rate, the user needs to provide two 55 kW feed pumps and an adjustable flow rate mud diversion supply pipeline.

Tags: mud cleaner for drilling fluids, mud cleaner, mud cleaner drilling, mud cleaner for sale, drilling mud cleaner, mud cleaner machine, mud cleaner drilling rig, mud cleaner desilter desander

Services

Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial sale;Your profits with quality parts and expert service.

Linear Motion Shale Shaker

Linear Motion Shale Shaker Decanter Centrifuge

Decanter Centrifuge Mud Cleaner

Mud Cleaner Vacuum Degasser

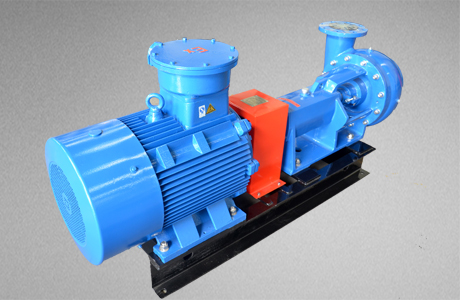

Vacuum Degasser Centrifugal Pump

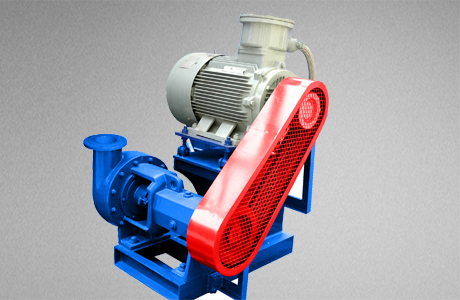

Centrifugal Pump Shear Pump

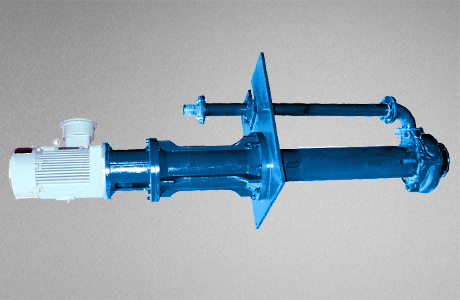

Shear Pump Submersible Slurry Pump

Submersible Slurry Pump Mud Agitator

Mud Agitator Mud Gun

Mud Gun Jet Mud Mixer

Jet Mud Mixer Desilter

Desilter