- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- Mud Tank

- LS1850 Shale Shaker

- Diesel Tank

- MD210 Drilling Mud Cleaner

- Balanced Elliptical Motion Shale Shaker

- Oilfield Drilling Mud Desander

-

Solids Control System

- Drilling Mud Cooling System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

Home > KOSUN News >

Equipments Commonly Used in Drilling Waste Management

Feb 23, 2015

Guide: Drilling waste management is to treat the solids generated during drilling and finally meet environment protection and discharge standards in countries and regions locally. It can meet the requirement of unlanding treatment of drilling mud, effectively prevent environmental pollution, save drilling mud and reduce drilling cost.

Drilling waste management is to treat the solids generated during drilling and finally meet environment protection and discharge standards in countries and regions locally. It can meet the requirement of unlanding treatment of drilling mud, effectively prevent environmental pollution, save drilling mud and reduce drilling cost. At present, there are many drilling waste management methods and devices with different treatment results.

Drilling waste equipments is to treat drilling waste and effectively reduce oil and water content in drilling waste, thus meeting statutory drilling waste discharge standards. The key equipment commonly used for drilling cuttings is Cuttings Dryer and Hi-G dryer.

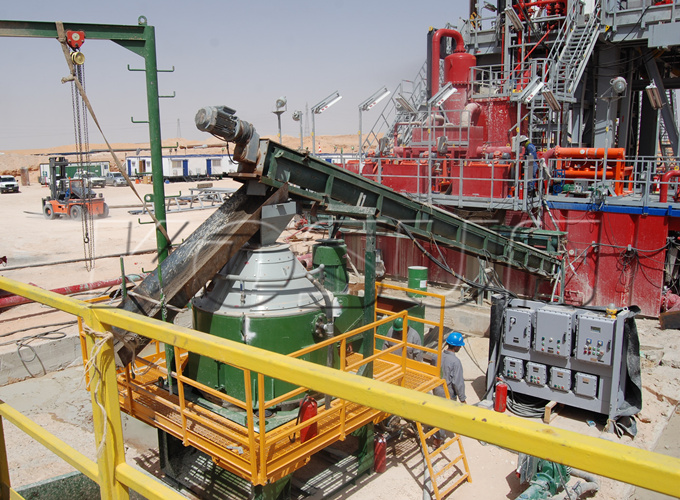

KOSUN vertical cuttings dryer can effectively treat water-based, oil-based, and synthetic-based drilling fluids, generate fairly dry cuttings, reduce the cuttings discharge, recover expensive drilling fluids and improve drilling cost-effectiveness.

VC-1000 cuttings dryer independently developed and manufactured by KOSUN features in mature performance and superior separation capacity. With top feed mode and built-in high speed centrifugal drum, it can achieve the maximum capacity of 60T/h, and OOC after treatment is below 5%. The recovered mud can be feeded into centrifuge for further treatment.

KOSUN VC-1000 Cuttings Dryer Operating at Algeria Drilling Site

Cuttings after treated by KOSUN Cuttings Dryer (OOC < 5% )

2. Hi-G Dryer

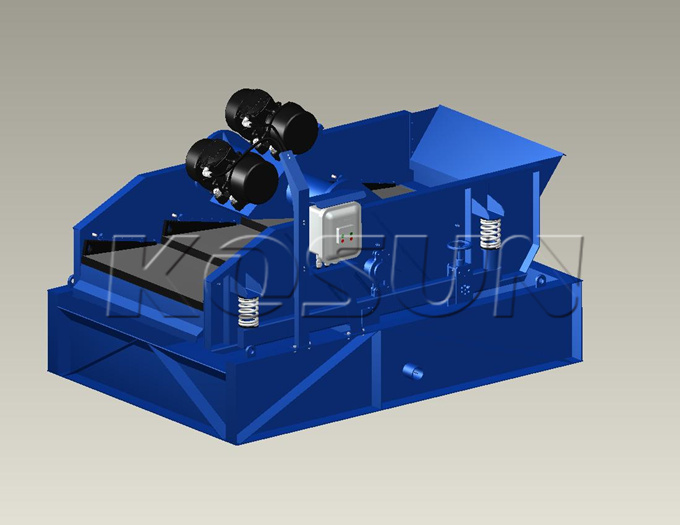

Hi-G dryer can also be used to recover oil-based, water-based and synthetic-based mud from drilling cuttings. Different quantity of Hi-G dryers can be equipped based on the conditions at drilling sites.

LS584-D Hi-G dryer independently developed and manufactured by KOSUN features in high G-force (adjustable), and superior screening and drying results. The screen frame tilt angle can be adjusted from -1° to +5° via AWD angle adjustment system while drilling. The liquid content on cuttings after treatment can reach 12%by weight at maximum, significantly reducing cost in drilling waste.

KOSUN LS584-D Hi-G Dryer