- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- Mud Tank

- Diesel Tank

- MD210 Drilling Mud Cleaner

- Balanced Elliptical Motion Shale Shaker

- Oilfield Drilling Mud Desander

-

Solids Control System

- Drilling Mud Cooling System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

Home > KOSUN News >

Solid control equipment: a key force in the industrial field

Jan 21, 2025

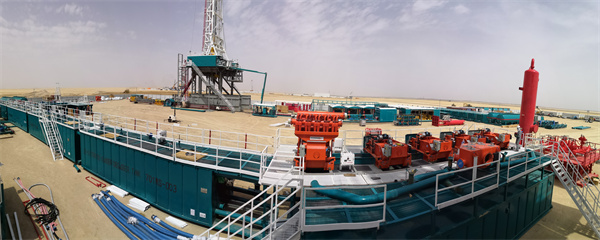

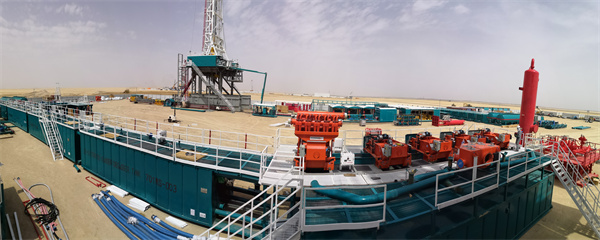

Solid control equipment plays an indispensable role in oil drilling, building piling, and many industrial scenarios involving solid-liquid separation. They operate silently, but have a profound impact on production efficiency, product quality, cost control, and environmental protection. With the continuous evolution of industrial technology, solid control equipment is also continuing to innovate to adapt to increasingly complex production needs.

1. Basic concept and working principle of solid control equipment

Solid control equipment, that is, solid control equipment, is mainly used to separate and treat solid particles in liquids. In oil drilling operations, drilling fluid (mud) carries a large number of solid particles such as cuttings during the cycle. The task of solids control equipment is to separate these particles from the drilling fluid so that the drilling fluid can be reused. Common solid control equipment includes vibrating screen, desander, desilter, centrifuge, etc., which work together according to different working principles.

The shale shaker is the first line of defense of the solid control system. Through high-frequency vibration, the drilling fluid flows on the screen, the larger particles of cuttings are trapped and discharged by the screen, and the liquid and smaller particles enter the next level of treatment equipment through the screen. The sand remover and mud remover use the principle of centrifugal force, when the liquid containing solid particles enters the cyclone along the tangential direction, the heavier particles are thrown to the wall under the action of centrifugal force, and move down the wall, and discharged from the bottom; Lighter liquid flows out of the top overflow port. Centrifuges work on the same principle of centrifugal force, but they can achieve a finer separation, can separate very fine solid particles from the liquid, often used for deep treatment of drilling fluids.

Ensure safe and efficient drilling operations

In the process of oil drilling, if the content of solid particles in drilling fluid is too high, the density and viscosity of drilling fluid will increase, and the fluidity and cutting-carrying capacity of drilling fluid will be affected. This will not only increase the wear of the bit, reduce the drilling speed, but also may cause serious accidents such as sticking. Solid control equipment can effectively separate solid particles in time, maintain the good performance of drilling fluid, and ensure the safe and efficient drilling operation. For example, in complex environments such as deep-sea drilling, high-performance solid control equipment is essential to ensure the stable operation of the drilling platform and drilling schedule.

Reduce production costs

Drilling fluid is an important consumable in oil drilling operations, and high-quality drilling fluid is expensive. Recycling drilling fluid through solid control equipment can greatly reduce the amount of new drilling fluid preparation, thus reducing production costs. According to statistics, a set of efficient solid control system can make the repeated utilization rate of drilling fluid reach more than 80%, which saves a lot of raw material procurement costs for enterprises. In addition, solid control equipment reduces the wear caused by solid particles on equipment, prolonging the service life of drilling equipment, and further reducing equipment maintenance and replacement costs.

An important barrier for environmental protection

Oil drilling operation will produce a large number of waste drilling fluid containing solid particles and chemicals, if discharged at will, it will cause serious pollution to the surrounding environment such as soil and water. Solid control equipment separates solid particles from liquid through effective treatment of drilling fluid, and the separated solids can be disposed of in landfill or other compliant disposal after harmless treatment, while the treated liquid can be safely discharged or further reused if it meets discharge standards. This greatly reduces the negative impact of oil drilling operations on the environment and helps the oil industry achieve green development.

Third, solid control equipment in other industrial fields of application expansion

Construction piling industry

In building piling construction, mud will also carry a lot of solid particles such as drilling slag. The solid control equipment can treat the piling mud, realize the recycling of the mud, and reduce the mud discharge. This not only helps to protect the environment, but also reduces the cost of piling construction, especially in urban centers and other areas with high environmental requirements, the application of solid control equipment is particularly important. For example, in the pile foundation construction of large urban complex, the use of solid control equipment to treat mud can effectively avoid the blockage of urban drainage system and environmental pollution caused by mud discharge.

Energy saving and environmental protection

In the context of global advocacy of energy conservation and emission reduction, solid control equipment manufacturers are committed to the development of more energy-efficient and environmentally friendly technologies. On the one hand, by optimizing the equipment structure and working parameters, the separation efficiency of the equipment is improved and the energy consumption is reduced. For example, the new centrifuges use efficient motors and advanced transmission systems to ensure separation while reducing energy consumption. On the other hand, the development of environmentally friendly separation media and treatment agents to reduce the potential harm to the environment. For example, some solid control equipment uses biodegradable flocculants to achieve efficient solid-liquid separation while reducing the environmental impact of chemicals.

Fine and multi-functional