- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- Mud Tank

- LS1850 Shale Shaker

- Diesel Tank

- MD210 Drilling Mud Cleaner

- Balanced Elliptical Motion Shale Shaker

- Oilfield Drilling Mud Desander

-

Solids Control System

- Drilling Mud Cooling System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

Home > KOSUN News >

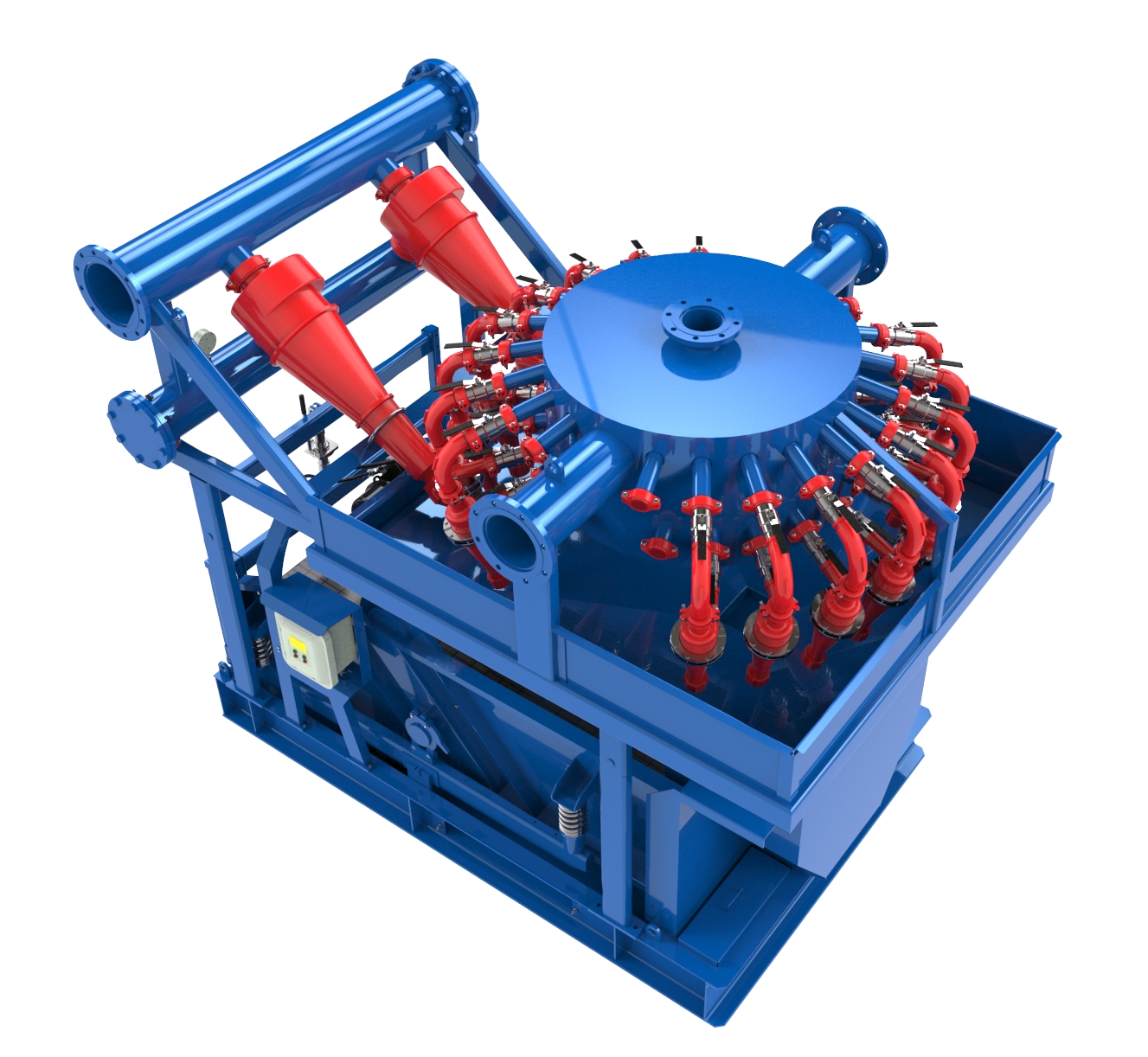

KOSUN Mud Cleaner: An Essential Tool in Drilling Operations

Feb 19, 2025

In the world of drilling, whether for oil, gas, or water, maintaining efficient and safe operations is crucial. One of the key pieces of equipment that helps achieve this is the mud cleaner. This article will explain what a mud cleaner is, how it works, and why it’s so important in drilling operations.

What is a Mud Cleaner?

A mud cleaner is a specialized device used in drilling operations to remove solid particles from drilling fluid, also known as "mud." Drilling mud is a critical component in drilling processes, as it helps cool and lubricate the drill bit, carry cuttings to the surface, and maintain pressure in the wellbore. However, as drilling progresses, the mud becomes contaminated with solid particles like rock cuttings, sand, and other debris. If not removed, these solids can damage equipment, reduce drilling efficiency, and increase costs.

The mud cleaner is designed to separate these unwanted solids from the drilling fluid, ensuring the mud remains clean and effective.

How Does a Mud Cleaner Work?

A mud cleaner typically combines two key pieces of equipment: a shale shaker and a desander/desilter.

Here’s how it works:

-

Shale Shaker:

The first stage of the mud cleaning process involves the shale shaker. The drilling fluid, mixed with cuttings, is pumped onto a vibrating screen. The screen allows the liquid mud to pass through while trapping larger solid particles, which are then discarded. -

Desander and Desilter:

After passing through the shale shaker, the mud still contains finer particles. It is then directed to the desander and desilter, which use centrifugal force to separate smaller solids. The desander removes medium-sized particles (like sand), while the desilter removes even finer particles (like silt). -

Clean Mud Return:

Once the solids are removed, the clean drilling fluid is returned to the mud system for reuse. This ensures the mud maintains its properties and continues to perform effectively.

Why is a Mud Cleaner Important?

-

Equipment Protection:

Solid particles in drilling mud can cause wear and tear on drilling equipment, including pumps, pipes, and the drill bit. By removing these particles, a mud cleaner helps extend the lifespan of the equipment and reduce maintenance costs. -

Improved Drilling Efficiency:

Clean drilling fluid flows more smoothly and maintains its properties better, leading to faster and more efficient drilling operations. -

Cost Savings:

Reusing cleaned mud reduces the need for fresh mud, saving on material costs. Additionally, fewer equipment repairs and replacements mean lower operational expenses. -

Environmental Benefits:

Properly cleaned mud can be reused, reducing waste and minimizing the environmental impact of drilling operations. -

Safety:

Clean mud helps maintain wellbore stability and prevents issues like stuck pipes or blowouts, ensuring safer drilling conditions.

Applications of Mud Cleaners

Mud cleaners are used in a variety of drilling operations, including:

-

Oil and Gas Drilling: To maintain efficient and safe drilling in both onshore and offshore operations.

-

Geothermal Drilling: To manage drilling fluid in high-temperature environments.

-

Water Well Drilling: To ensure clean drilling fluid for water extraction projects.

-

Mining and Construction: To remove solids from drilling fluids used in exploration and foundation drilling.