- Home

- Products

-

-

Solids Control Equipment

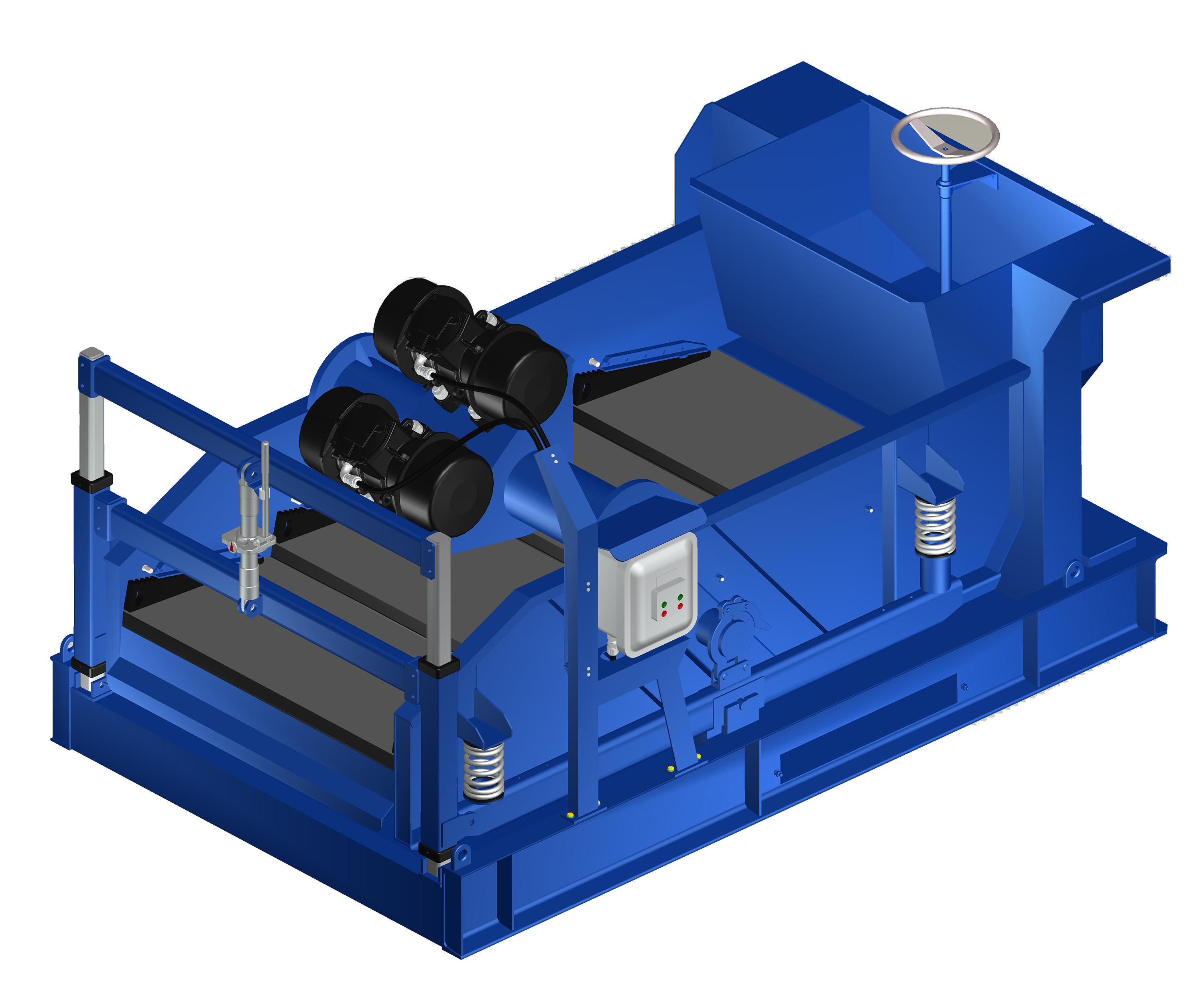

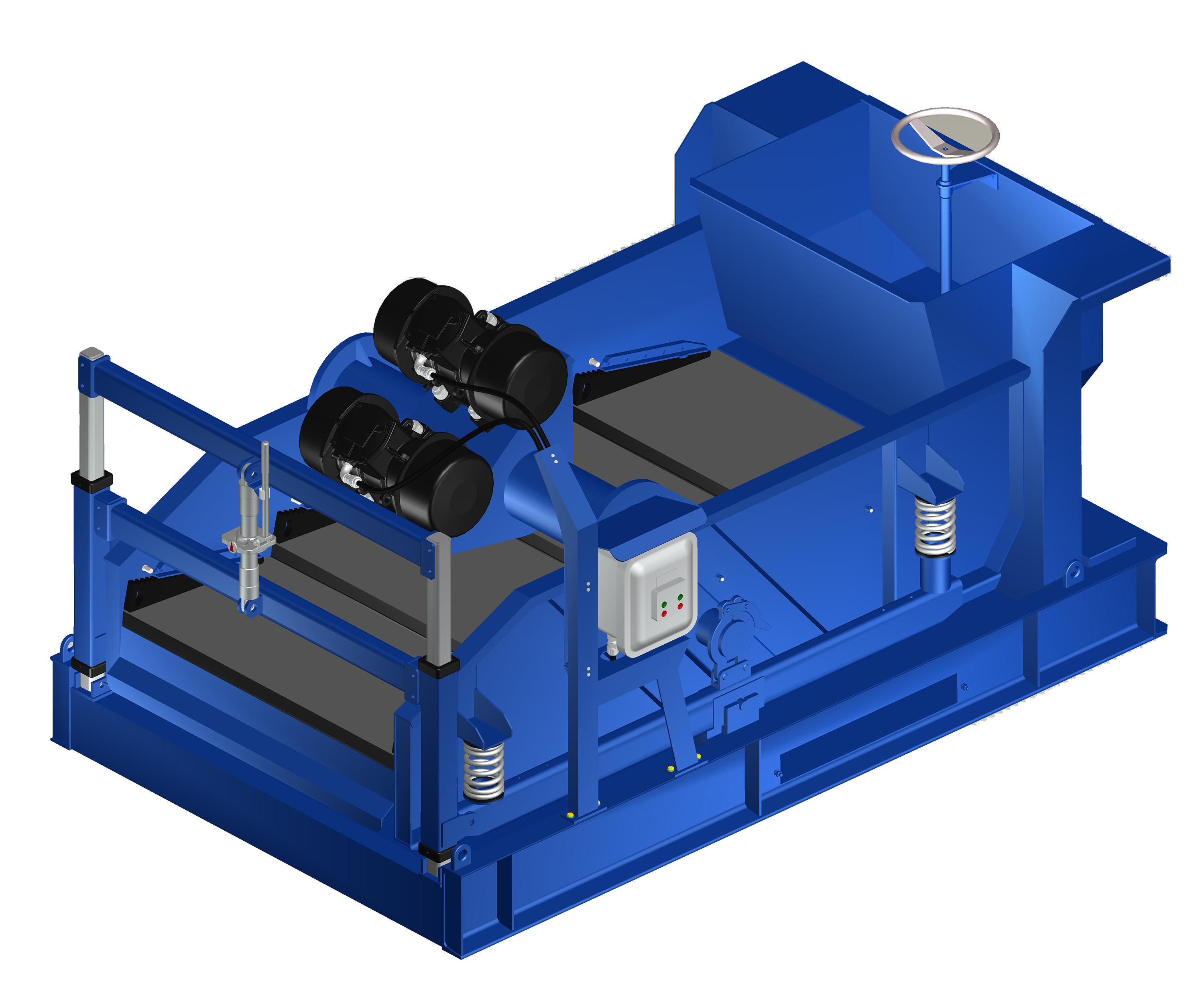

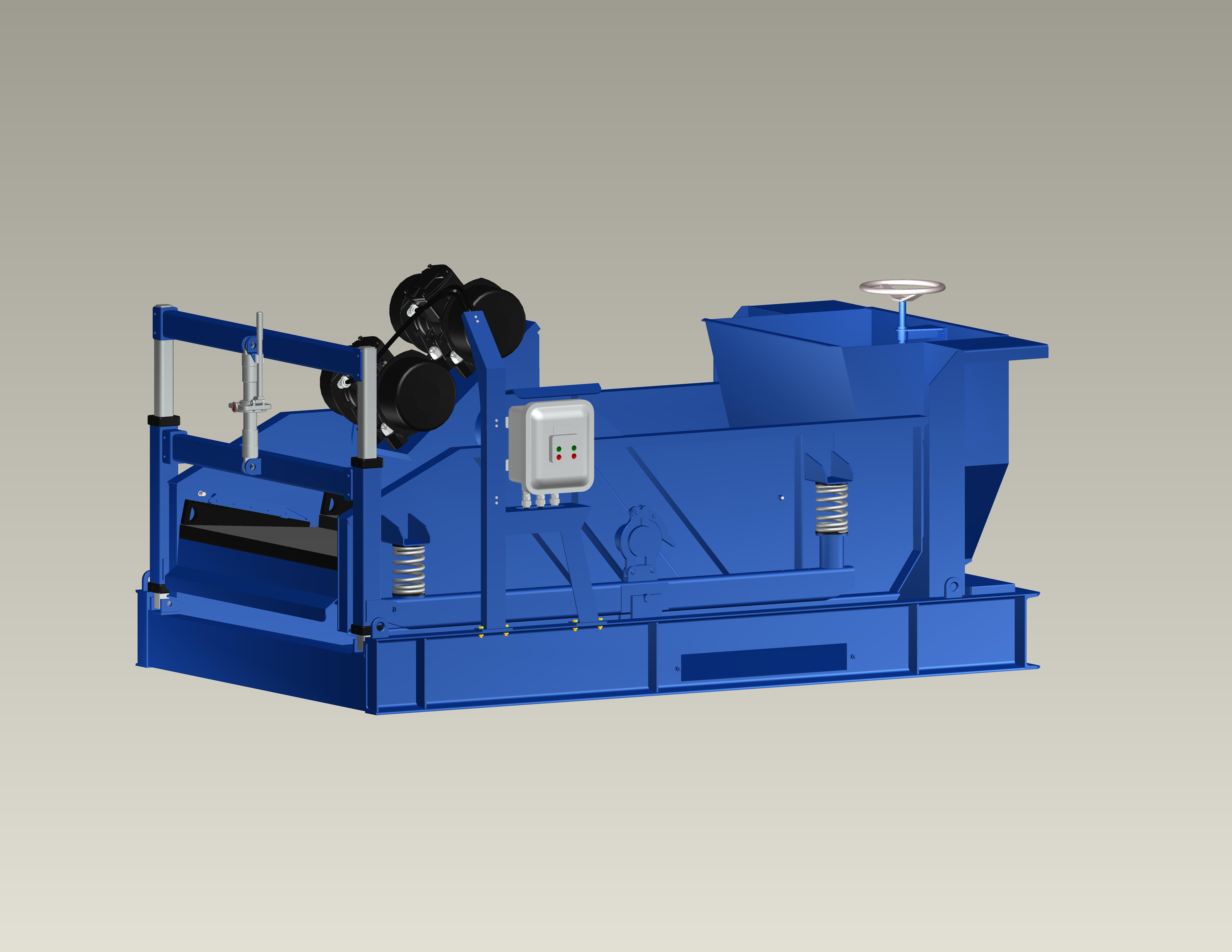

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- Mud Tank

- LS1850 Shale Shaker

- Diesel Tank

- MD210 Drilling Mud Cleaner

- Balanced Elliptical Motion Shale Shaker

- Oilfield Drilling Mud Desander

-

Solids Control System

- Drilling Mud Cooling System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

Home > KOSUN News >

Factors affecting the operation of mud shale shaker

Feb 14, 2025

In the solid control system of oil drilling, the mud shale shaker belongs to the first level solid control equipment.

The drilling fluid returned from the well through the elevated manifold passes through the shaker first, and then enters the other solid control equipment behind for processing.

Drilling fluid vibrating screen is a filterable solid-liquid separation equipment, but also the solid control system in the first separation and separation efficiency of the equipment,

through the vibrating screen can separate and remove a large number of harmful solid phase, effectively clean the large particles in the drilling fluid solid phase,

then what factors will affect the work efficiency of the vibrating screen, let's take a look at it.

The drilling fluid returned from the well through the elevated manifold passes through the shaker first, and then enters the other solid control equipment behind for processing.

Drilling fluid vibrating screen is a filterable solid-liquid separation equipment, but also the solid control system in the first separation and separation efficiency of the equipment,

through the vibrating screen can separate and remove a large number of harmful solid phase, effectively clean the large particles in the drilling fluid solid phase,

then what factors will affect the work efficiency of the vibrating screen, let's take a look at it.

First, there are many forms of motion of the mud vibrating screen, we commonly used is the linear motion of the vibrating screen, linear motion is to put the oscillator

on the front of the center of gravity of the system above, so that the screen frame produces linear motion, so as to remove the solid phase compared with other motion

trajectory vibrating screen, linear motion vibrating screen has a stable drilling fluid delivery speed, screen surface is relatively flat, It has high working efficiency,

and it can also tilt the screen surface slightly to improve the time of drilling fluid on the screen surface, thereby improving the treatment effect.

on the front of the center of gravity of the system above, so that the screen frame produces linear motion, so as to remove the solid phase compared with other motion

trajectory vibrating screen, linear motion vibrating screen has a stable drilling fluid delivery speed, screen surface is relatively flat, It has high working efficiency,

and it can also tilt the screen surface slightly to improve the time of drilling fluid on the screen surface, thereby improving the treatment effect.

Second, the amplitude and frequency of the mud vibrating screen is also one of the important factors affecting the efficiency of the vibrating screen, the vibration frequency

of the vibrating screen, the greater the rotation speed, the higher the vibration frequency, the better the effect of screening solid phase; In theory, the larger the amplitude of

the vibrating screen, the better the treatment effect, but after the amplitude increases, the greater the force the vibrating screen is subjected to, it will shorten the service

life of the vibrating screen, so a reasonable design of the amplitude can improve the working efficiency of the vibrating screen and the service life of the vibrating screen.

of the vibrating screen, the greater the rotation speed, the higher the vibration frequency, the better the effect of screening solid phase; In theory, the larger the amplitude of

the vibrating screen, the better the treatment effect, but after the amplitude increases, the greater the force the vibrating screen is subjected to, it will shorten the service

life of the vibrating screen, so a reasonable design of the amplitude can improve the working efficiency of the vibrating screen and the service life of the vibrating screen.

Third, the inclination of the mud vibrating screen and the mesh number of the screen is also one of the factors affecting the work efficiency of the vibrating screen, the general constant single layer vibrating screen has 2-4 screens, the front screen is generally flat, and the last screen has a certain tilt Angle. This is designed so that the drilling fluid can efficiently pass through the front screen and improve the treatment effect when passing through the back screen. The mesh number of the screen is also very important, we are dealing with different materials, need to achieve different treatment effects, need to choose the appropriate mesh of the screen can improve the treatment effect and achieve our treatment effect, if the mesh number is too high will reduce our work efficiency, or the mesh number is too low will affect our treatment effect.