- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- LS606 Shale Shaker

- Mud Tank

- LS1850 Shale Shaker

- Diesel Tank

- Dome-shaped mud cleaner

- Vertical cyclone desilter

- KQG30 Automatic Tank Cleaning

- MD210 Drilling Mud Cleaner

-

Solids Control System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

- Drilling Mud Cooling System

- Liquid Mud Plant (LMP )

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

Home > KOSUN News >

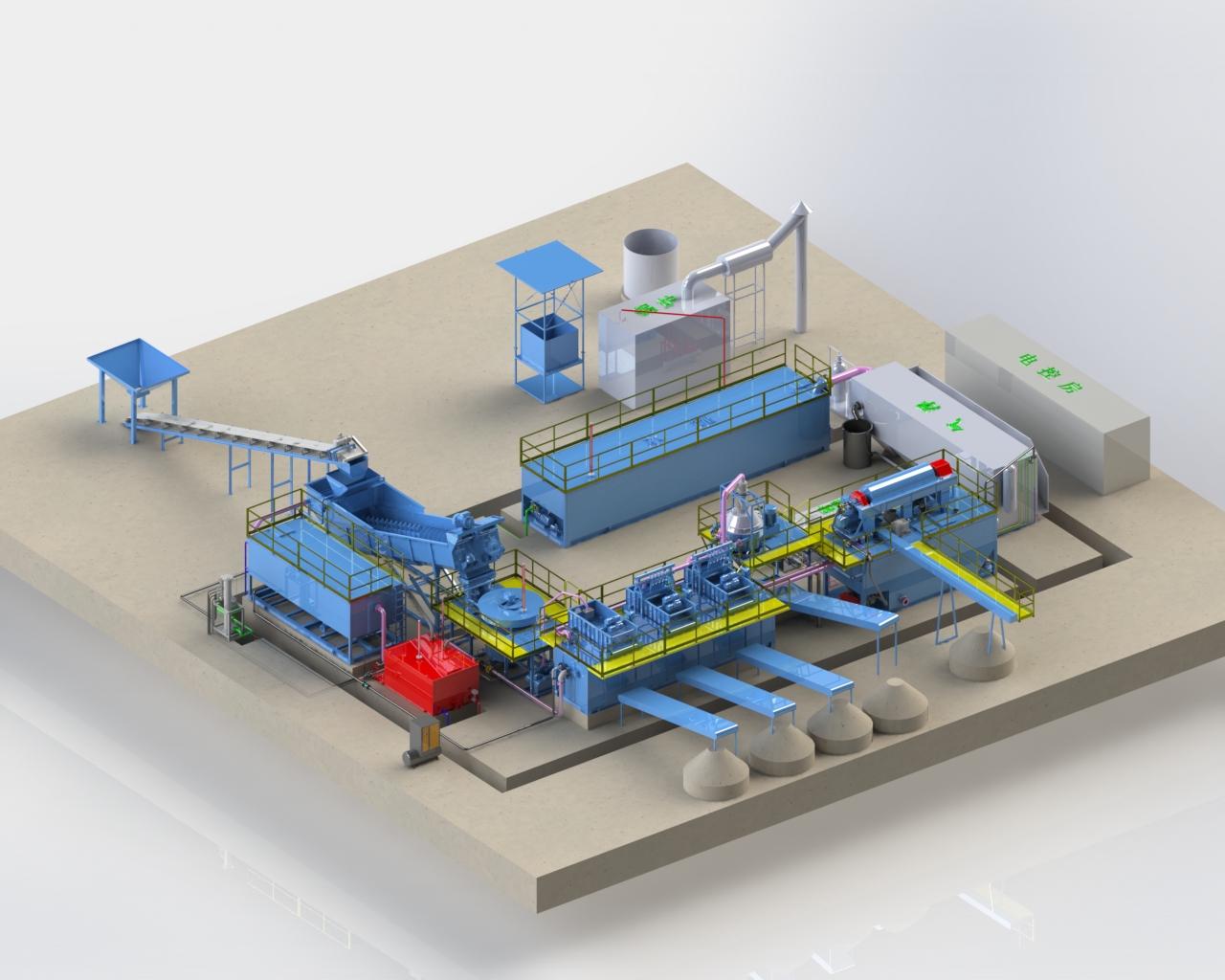

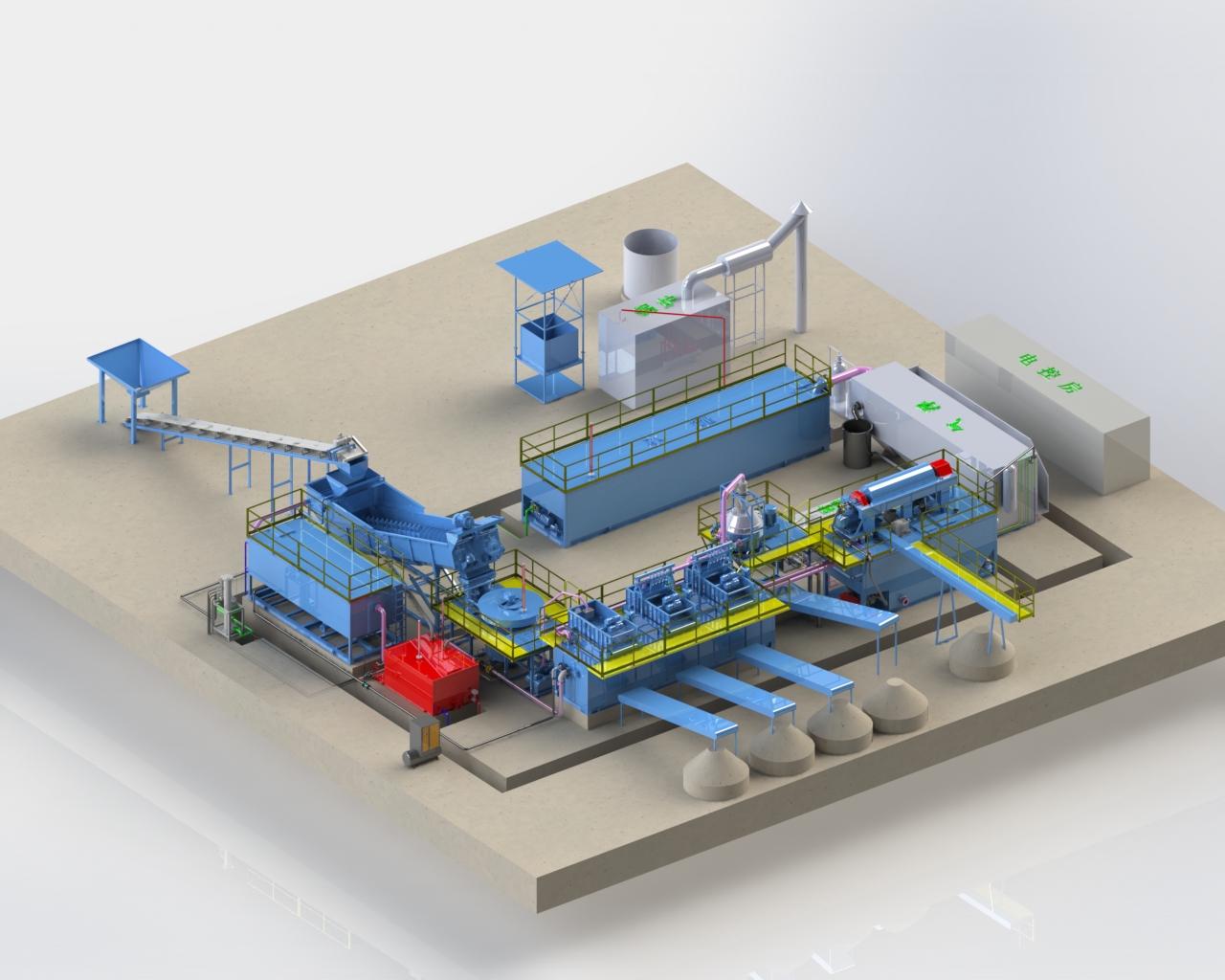

Application of oil sludge treatment equipment in drilling waste treatment

Jun 24, 2025

The selection of suitable oil sludge treatment equipment plays an important role in the treatment effect of oil sludge.

Oil sludge treatment typically involves the use of various equipment to separate and process the sludge into its constituent components.

Commonly used oil sludge treatment equipment includes:

Commonly used oil sludge treatment equipment includes:

Thermal desorption units: These units utilize heat to separate the oil, water, and solids in the sludge. The heat causes the oil to evaporate, leaving behind the water and solid residues.

Decanter centrifuge: Centrifuges use centrifugal force to separate the oil, water, and solids in the sludge. The high-speed rotation of the centrifuge causes the heavier solids to settle, while the lighter oil and water are discharged separately.

Drying screen: It is used to recover oil-based drilling fluid in drilling cuttings so that the proportion of liquid phase in drilling cuttings will be less than 10%, which can significantly reduce the cost of waste discharge.

Filter presses: Filter presses can be used to separate the solids from the oil and water fractions of the sludge.

Dosing device: Chemicals can be added to the sludge to enhance the separation of oil, water, and solids. This can be done through various processes such as flocculation, coagulation, or emulsion breaking.

Oil/water separation systems: These systems use gravity or coalescence techniques to separate the oil and water fractions in the sludge, allowing for the recovery of usable oil.

Screw Pump: Used to transport sludge.

Storage tank: Used to store sludge.

Screw conveyor:It is used to transport sludge.

The selection and combination of equipment depend on factors such as the characteristics of the oil sludge, treatment objectives, environmental regulations, and the desired final products or waste disposal methods. The specific equipment used and their configuration will vary based on the specific requirements of the oil sludge treatment process.

Tag: oil sludge treatment equipment, oil sludge treatment

Tag: oil sludge treatment equipment, oil sludge treatment